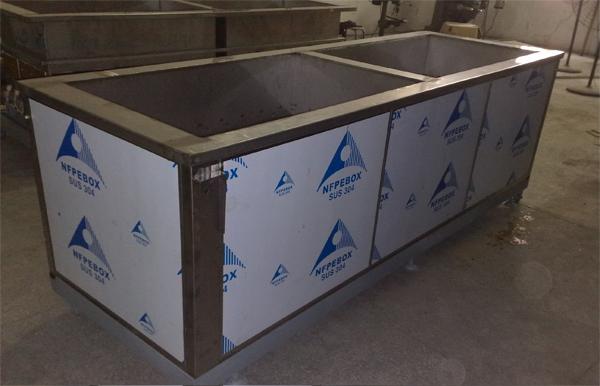

ultrasonic cleaner system

(一).ultrasonic cleaner system for single-slot, full stainless steel, acid, alkali, beautiful and durable, the use of alkaline or acidic aqueous solvents as cleaning agents for parts plated plated plated after pre-treatment and cleaning, watch parts, hardware and machinery parts, jewelry, lenses, spectacle frames and glassware cleaning. And control the use of cleaning some part of sub-structure, easy to use, appropriate for maintenance.

(二).ultrasonic cleaner system composition and functions of major components

1.0 composition

UCE Series ultrasonic cleaning machine, the ultrasonic generator, transducer, cleaning tank, automatic temperature control heating and housing and so on.

2.0 The main components of function

2.1 Ultrasonic generator: generate higher than 20KHZ super audio signal.

2.2 Transducer: The ultrasonic generator converts electrical energy super-audio frequency mechanical oscillations and the incoming cleaning liquid, so as to achieve the purpose of ultrasonic cleaning.

2.3 Ultrasonic cleaning tank: containing cleaning fluid.

2.4 Customers can request the actual workpiece Gaga in the cleaning tank top heating devices, to achieve the best cleaning effect increases.

(三).ultrasonic cleaner system, the basic working principle

The use of super audio power than 28KHZ, the transducer converts the incoming high-frequency mechanical vibration to the cleaning solution. Ultrasonic cleaning fluid density in the forward phase of radiation, so that the liquid flow, and have kept tens of thousands of tiny bubbles. These bubbles are the longitudinal ultrasonic wave propagation in the negative pressure zone formation and growth, and rapidly closed in positive zone (off). The formation of tiny bubbles, generating cavitation phenomenon known as rapid closure. In the cavitation bubbles formed when more than 1000 closed the instantaneous atmospheric pressure. Instantaneous pressure generated continuously, like a series of small explosions continue to bombard the surface, so that the object and the cracks in the dirt quickly peel off. This cavitation erosion is the basic principle of ultrasonic cleaning.

(四).ultrasonic cleaner system for use

1.0 Preparation before start

1.1 Check the washing machine is installed smoothly, chassis ground is reliable;

1.2 the power switch to "off" position, check the power supply is in compliance with requirements;

1.3 the washing machine on the black cable to the high-frequency ultrasonic generator outlet, and tighten;

1.4 Close the side drain valve;

1.5 into the cleaning fluid to clean the parts to be completely immersed in cleaning fluid, the liquid surface with the cylinder away from 10mm ~ 20mm appropriate.

2.0 Operating Procedures

2.1 power;

2.2 In accordance with process requirements, a heating device to adjust the temperature controller to the desired temperature;

2.3 When you reach the set temperature, the corresponding indicator light goes off, turn on the ultrasonic switch ultrasonic generator, the corresponding indicator light, ultrasonic begin work;

2.4 Ultrasonic cleaning machine stop working before, you should turn off the ultrasonic switch, rotary temperature control regulator to 0 ℃, and then cut off the power.

(五).things ultrasonic cleaner system uses the top note (pay special attention to points 1, 2)

1.0 When cleaning the tank without cleaning fluid must not start the ultrasound, which can cause damage to the transducer of the serious consequences;

No cleaning solution or 2.0 tank below the liquid surface cleaning requirements, the absolute prohibition of heat, otherwise it will damage the heating plate;

3.0 may not be the object directly into the ultrasonic cleaning tank, if any foreign matter falling into the bottom of the tank should be promptly removed, otherwise it will damage the ultrasonic transducer;

4.0 is not the object splashing transducer and ultrasonic generator;

5.0 must not use flammable liquid solution for cleaning;

6.0 new ones when the old fluid, exhaust heat from the liquid and the temperature controller should be placed at 0 ℃ and room temperature, ultrasonic switch to the off position in the closed position under;

7.0 Inspect and clean control of electrical appliances.