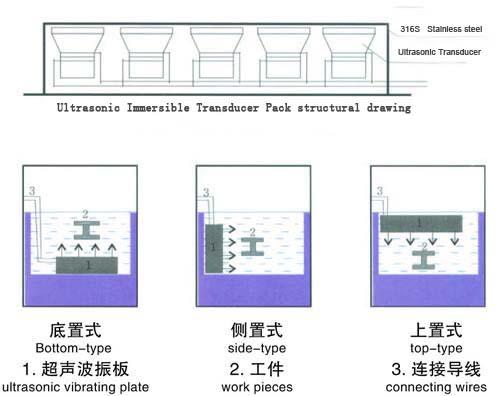

immersible ultrasonic transducers

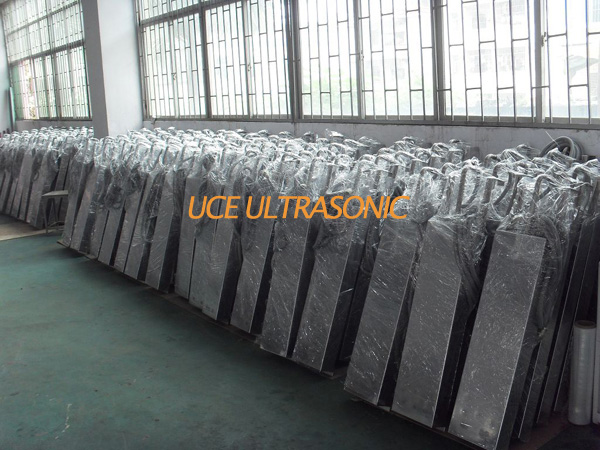

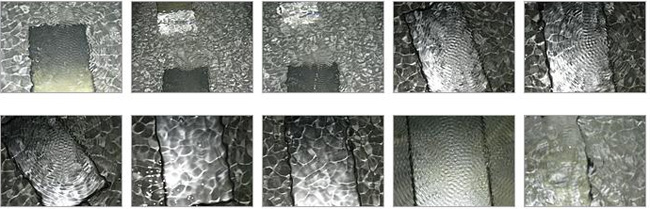

immersible ultrasonic transducers device consists of two shock plate and the ultrasonic generator parts. When the standard models of ultrasonic cleaning machine is not applicable to a particular work environment, in addition to special specifications can be custom-made, but also can be put into ultrasonic shock plate device. In the existing equipment, if there are common ultrasonic cleaning tank, ultrasonic vibration plate can be added to devices, ultrasonic cleaning machine converted into a fully automatic or semi-automatic ultrasonic cleaning machine.

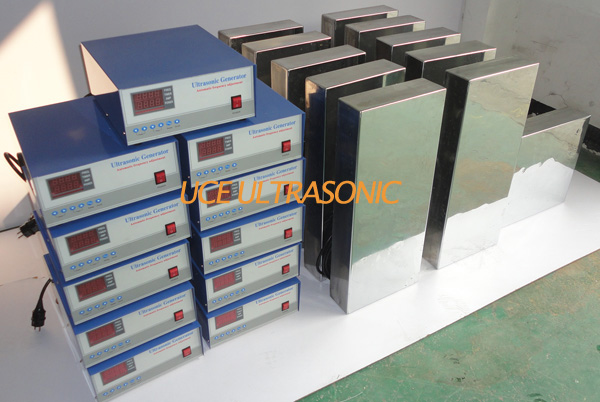

| Type | Diamention(mm) | Frequency (Khz) | Power(W) | Ultrasonic Transducer |

| UCE-UITP300W | 300*190*100 | 25,28,33,40,80,130 | 300 | 6 |

| UCE-UITP600W | 360*275*100 | 25,28,33,40,80,130 | 600 | 12 |

| UCE-UITP1000W | 450*350*100 | 25,28,33,40,80,130 | 1000 | 20 |

| UCE-UITP1200W | 470*380*100 | 25,28,33,40,80,130 | 1200 | 24 |

| UCE-UITP1500W | 520*450*100 | 25,28,33,40,80,130 | 1500 | 30 |

| UCE-UITP1800W | 560*450*100 | 25,28,33,40,80,130 | 1800 | 36 |

| UCE-UITP2000W | 650*450*100 | 25,28,33,40,80,130 | 2000 | 40 |

| UCE-UITP2400W | 740*520*100 | 25,28,33,40,80,130 | 2400 | 48 |

| UCE-UITP3000W | 820*540*100 | 25,28,33,40,80,130 | 3000 | 60 |

| UCE-UITP5000W | 1200*590*100 | 25,28,33,40,80,130 | 5000 | 100 |

| OEM Ultrasonic Immersible Transducer Pack(Size, Frequency,Power) | ||||

immersible ultrasonic transducers This series of products is suitable to cleaning work pieces of various industries;such as plating components cleaning before plating,electronic,hardware machinery parts,clock and watch parts,semiconductor sillcon chips,glass vessels,bijouterie,spectacle frame, etc.

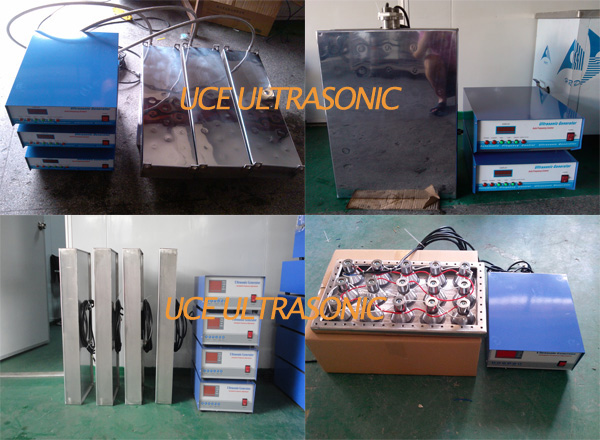

2. immersible ultrasonic transducers Mounting types Technical Information:

Type Description

A

Mounting to tank wall with threaded duct nipple and fastening bracket. Cable through the tank wall.

B

Mounting to tank wall with threaded duct nipple and fixing nipple. Cable through the tank wall.

C

Mounting to tank wall with hanging hooks. Rigid stainless steel tube for cable over the tank top.

D

Mounting to tank wall with hanging hooks. Flexible metal armoured 1 m hose for cable over the tank top.

E

Mounting to tank bottom. Rigid stainless steel tube for cable through the tank wall.

F

Mounting to tank bottom. Rigid stainless steel tube for cable over the tank top.

G

Mounting to tank bottom. Flexible metal armoured 0,5 m hose for cable through the tank wall.

H

Mounting to tank bottom. Flexible metal armoured 1,5 m hose for cable over the tank top.

X

Non-standard mounting