|

Tubular Equipment

Type

|

Tubular Transducer

Type

|

Frequency

(KHz)

|

Ultrasound

Output(W)

|

Total Length

(mm)

|

Diameter

(mm)

|

Static Capacity

(pF±10%)

|

|

UCE-UE1

|

US-61

|

15-28

|

1000

|

500

|

Φ50-55

|

68000

|

|

UCE-UE5

|

US-25

|

15-28

|

1500

|

850

|

Φ50-55

|

68000

|

|

UCE-UE6

|

US-16

|

15-28

|

2000

|

1100

|

Φ50-55

|

132000

|

四、Key technology information:

1、frequency range:15KHz ~ 60 KHz。

2、usually frequency:20kHz

3、unit power:1000W、1100w,1200w,1300w ,1500W、2000W,also can be used for parallel connection

4、Head tool material:Stailess Steel,Titanium,also would like custom for our user。

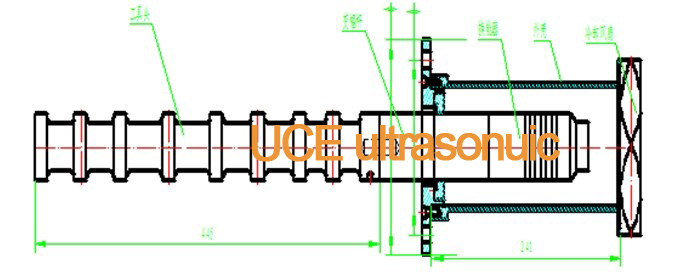

5、Ultrasonic vibration parts size: Φ160mm×800mm

6、Ultrasonic vibration parts weight:12 kg

7、 Driver: analog power, power supply, frequency control type of automatic tracking, flowing pressure protection, adjustable power size.

8 、Driving power typical size:350×250×120mm

9、 Driving power typical weight:18 kg

| Working frequency | 20kHz | 20kHz | 20kHz | 20kHz |

| Max power | 500W | 1000W | 1500W | 2000W |

| Handling capacity L/h | ≤500 | ≤800 | 200-1000 | 300-1600 |

| Apply | laboratory | Production line,can be used in combination | ||

| reaction tank | 15L,20L,35L,stainless steel | |||

| allow pressure | max≥5 MPa | |||

| allow temperature | max≥350℃ | |||

High-power ultrasonic sound chemical processing system by ultrasonic vibration wave components and special driving power and the reaction kettle of three main parts: ultrasonic vibration high-power ultrasonic transducer, including the horns, tool (emission head), is used to produce the ultrasonic vibration and vibration energy in the liquid. The input power transducer will convert energy, i.e. ultrasonic. Its form is made in the longitudinal slip back transducer, amplitude in motion a few microns. Such amplitude is not enough, and power density directly use. According to the design of ultrasonic transformers, isolation reaction to enlarge amplitude transducer, also solution and the ultrasonic vibration system has fixed. Tools and horns, decreasing vibration transmitted ultrasonic energy will head, again by the tool tool head will launch ultrasonic energy to chemical reaction liquid.

2 and working principle:

The study of ultrasonic chemistry has involves chemistry, material science, environmental protection, and many other areas, including in organic synthesis, management difficult biodegradable toxic organic pollutants in application. With strong ultrasonic vibration propagation direction, medium strength, in liquid can produce cavitation phenomenon, etc. Ultrasound can prompt cannot occur under routine conditions of chemical reaction occurs or improve the response speed and existing reaction degree. But these are not sound direct role in response, generally considered the matter of the above phenomenon occurred mainly comes from the mechanical effect and ultrasonic cavitation, they changed the reaction conditions and environment.

Mechanical function, will introduce chemical reaction system, ultrasonic wave can make the material for severe forced movement, ChanXiangLi accelerated material transfer and diffusion, but instead of mechanical mixing, can make the material from the surface, thus interface update.

Cavitation -- in some cases, to produce the effect of ultrasonic cavitation mechanism associated with sound, the cavitation refers to the sound, the tiny bubbles exists cavitation (liquid) what happened a series of dynamic process: oscillation, expand, shrinkage and collapse.

The above two action is ultrasound can accelerate and rev. The main reason for chemical reaction.

3, work mode:

Focusing probe type high-power ultrasonic sound chemical processing system can have two kinds of work.

One way is by liquid in the normal distribution and containers, ultrasound liquid, insert the launch ultrasonic. The liquid in the treatment of container, also will be strong ultrasonic action. The reaction tank size or temperature. Generally speaking, of the same size of the container, the liquid flow in the smaller containers, or stay longer, the intensity of ultrasonic action is stronger also, of course, also less. Conversely, the shorter time control ultrasonic wave function, low intensity, flow (output) is higher. This way is also applicable to the application of anti-scaling removal.

Another way is with my company specialized in ultrasonic reaction kettle, constitute a complete sonochemical reactors. By the end of reaction caldron liquid flows from the effect, after ultrasonic, on the other side. In this way, the chemical changes, the effect of the system is the minimum immediate.

US equipment for biodiesel