Ultrasonic reactor for biodiesel also named High-power ultrasonic sound chemical processing system ,which is widely used in biodiesel refining,mixed,chemical mixed,food ,etc. they can speed up the reaction to save much time for you.

|

Tubular Equipment

Type

|

Tubular Transducer

Type

|

Frequency

(KHz)

|

Ultrasound

Output(W)

|

Total Length

(mm)

|

Diameter

(mm)

|

Static Capacity

(pF±10%)

|

|

UCE-US1

|

US-61

|

25-27

|

1000

|

500

|

Φ50-55

|

68000

|

|

UCE-US5

|

US-25

|

25-27

|

1500

|

850

|

Φ50-55

|

68000

|

|

UCE-US6

|

US-16

|

25-27

|

2000

|

1100

|

Φ50-55

|

132000

|

Features

Since cavitation occurs on all outside areas of the tube, ultrasonic energy distribution in the tank is very uniform, with an excellent cleaning effect.

The output power of the tubular transducer equipment is not affected by the depth of solution, capacity of bath, variation of solution temperature and so on.

Thanks to structural tubular equipment, the application range is wider than a conventional transducer equipment. It is best matched to vacuum and high pressure cleaning and chemical processing.

It has one and half to two times the life can be maintained compare with conventional transducer equipment.

The round shape makes it possible to install very simply in every place so that the designing of the bath is simple.

The tube structure guarantees watertightness.

Application

It is widely used in the fields of ultrasonic cleaning, biochemistry, food, chemical and pharmaceutical industry. In biochemistry industry, the tubular transducer equipment can be used for emulsification, separation, homogenization, refining and catalyzing reaction and it can increase production capacity. The tubular transducer equipment plays an important role in the even stirring of homogenates in food processing.

In the chemical industry, it is suitable for cleaning pipeline, tanks and kettles. The catalyzing effect of ultrasonic is quite obvious when the tubular transducer equipment used in the refinement of scavenge oil and palm oil to biodiesel, as the efficiency can be improved more than tenfold. Therefore, it will have expansive applications in the petro-chemical industry .

To design and fabricate tubular transducers in different sizes and specifications according to customers' requirements.

Catalyzing application of twelve pieces of tubular transducers used in the refinement of biodiesel from scavenge oil.

Ultrasonic tubular transducer equipment(UCE serial)

一,The feature:

Since cavitation occurs on all outside areas of the tube, ultrasonic energy distribution in the tank is very uniform, with an excellent cleaning effect.

The output power of the tubular transducer equipment is not affected by the depth of solution, capacity of bath, variation of solution temperature and so on.

Thanks to structural tubular equipment, the application range is wider than a conventional transducer equipment. It is best matched to vacuum and high pressure cleaning and chemical processing.

It has one and half to two times the life can be maintained compare with conventional transducer equipment.

The round shape makes it possible to install very simply in every place so that the designing of the bath is simple.

The tube structure guarantees watertightness

二,the specification

power:1000W-2000W

frequency:25-27KHZ;

working length:458mm-1123mm

Total length:600mm-1200mm

Input Voltage :AC 220V

Material: stainless steel 316

三,operating instructions

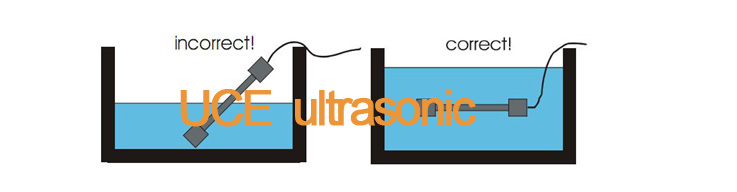

the liquid are injected into container, It is better for the liquid have come up to the tubular 100mm

Turn on the power switch

Press the on/off button, Begin to work, LCD display “R”, then press the on/off button, stoping working

四,announcements

the generator must be matched tubular.

Forbit to start the Ultrasound source when there aren’t the liquid in the tank. so as not to damage the transducer.

Prevent the hard material impatching the tubular, and don’t let the workpiece lay up the surface of the tubular.

Place the tubular at dry and ventilated places.

If The power supply voltage change beyond allowed scope, should suspend using.

If the ultrasonic effect suddenly become weak. ultrasonic circuit may have the malfunction, Should the reuse after maintenance,

The ultrasonic generator should be used under 40 ° c environment.

五, care and maintenance

Regular cleaning dirt and other attachments,keep the surface of tubular clean.

where possible maintain a well ventilated environment;

the equipment should be used and maintained by a special person, to avoid the illegal operation.

六, anomaly and the fault response.

1,no ultrasonic, A: whether does voltage of examination power source accord with a requirement?

B:if the thrum and power switch are in good condition?

C: if protective tube are good?

2, ultrasonic weak.A:if the tube of generator power is normal?

B:if power supply voltage is too low?

七, the working method:

Focus on high-power ultrasonic probe Sonochemical processing system, there are two ways of working.

One way is to be handled in the normal fluid flow and reaction vessels, ultrasound into the liquid in the first launch, launch ultrasound. Be processed liquid in the container stream over the same time, the role was a strong ultrasonic. Reaction vessel size or the temperature can be high or low. In general, the same size container, the liquid flow of the smaller, or stay in the container the longer the role of ultrasound intensity is stronger, of course, the less output. On the contrary, the control ultrasonic shorter, then the ultrasonic intensity on the low flow (ie production) higher. This approach also applies to Anti-fouling applications.

Another approach is to use my company-specific distribution of ultrasonic reactor to form a complete sonochemical reactor. Processed at one end of the liquid from the reactor flows through the role of ultrasound, another from the other side of the outflow. In this way the original chemical system, the smallest changes, the effect immediate.

八,According to chemical reaction conditions, materials and purpose different from the general equipment of the following:

1000W the following systems: mainly used for laboratory and small-scale or pilot systems

1000W system: for maximum yield of less than 800 L / h of chemical reaction production equipment

1500W system: for production of 200-1200 L / h of chemical reaction production equipment

2000W system: for production of 300-1600 L / h of chemical reaction production equipment

Ultrasonic reactor biodiesel