Ultrasonic vibrating sieve

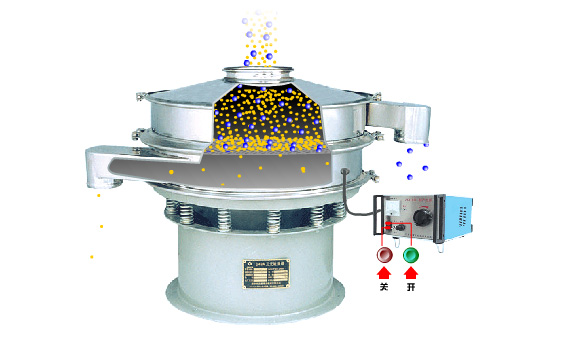

Ultrasonic vibrating screen is 220V, 50Hz electrical energy into high frequency 38KHz power input, ultrasonic transducer, turning it into 38KHz mechanical vibration, achieve the efficient screening and net cleaning purposes and an easy job to do solve the strong adsorption, easy agglomeration, high static and high precision, high density and light density screening problem. Has superior performance! The screening of ultra fine powder will be easy.

Ultrasonic vibration sieve system is a simple, practical and reliable screening system, is the most effective way to solve the clogging, is a major breakthrough in the domestic industry screening technology.

Ultrasonic vibrating screen is a derivative of the rotary vibration sieve, ultrasonic vibration screen controller and combine together in the ultrasonic vibration wave screen superimposed on a high frequency and low amplitude, ultra fine powder receiving enormous ultrasonic acceleration, so that the screen material always maintain a state of suspension, thereby inhibiting the adhesion and friction, flat down, such as wedge net blocking factors, so as to solve the strong adsorption, easy agglomeration, high static and high precision, high density and light density screening problem, ultra-fine powder screening will no longer be difficult, especially for high quality, fine powder users. Ultrasonic vibration sieve model has diameter 1800mm diameter 600mm-, ultrasonic vibration sieve material has stainless steel ultrasonic vibration sieve and carbon steel ultrasonic vibration sieve.

Ultrasonic vibration sieve:

In 1, to achieve high precision, high sieving mesh and narrow size range control.

2, can be single layer and multi-layer use, a set of intelligent ultrasonic generator at the same time using three transducers.

3, complete screen self-cleaning function: more than 500 mesh sieving, no clogging, no screening efficiency attenuation.

4, really solve the strong adsorption, easy to reunite, high static, high precision, high density, light weight and other screening problems.

5, to ensure that the characteristics of the processing of the same material.

6, screening accuracy can be increased by 70% - 1, the yield can be increased by 0.5-10 times.

|

UCE-400 |

UCE-600 |

UCE-800 |

UCE-1000 |

UCE-1200 |

UCE-1500 |

UCE-1800 |

UCE-2000 |

Effective screening |

Φ340 |

Φ540 |

Φ730 |

Φ900 |

Φ1100 |

Φ1400 |

Φ1700 |

Φ1886 |

Effective screening |

0.0907 |

0.2289 |

0.4183 |

0.6359 |

0.9499 |

1.5386 |

2.2687 |

2.7922 |

Screen specifications |

80~600 |

|||||||

number |

1-3 |

1-3 |

1-3 |

1-3 |

1-3 |

1-3 |

1-3 |

1-3 |

POWER |

0.18 |

0.25 |

0.55 |

0.75 |

1.1 |

1.5 |

2.2 |

2.2 |

Ultrasonic vibrating sieve