Ultrasound welding converts 50/60 Hz current into 15, 20, 30 or 40 KHz energy through an ultrasonic generator. The converted high-frequency electrical energy is converted again into mechanical motion of the same frequency through a transducer, which is then transmitted to the weld head through a set of amplitude-changing horn devices. The welding head transmits the received vibration energy to the joint of the workpiece to be welded. In this area, the vibration energy is converted into heat energy by friction, and the plastic is melted.

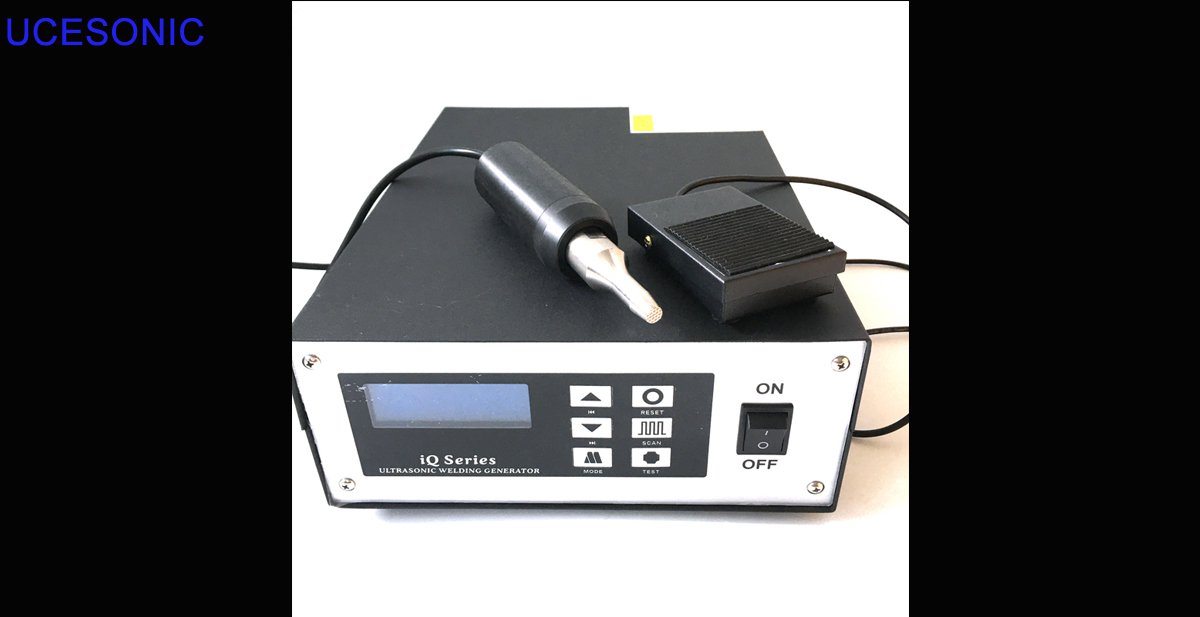

Ultrasound can not only be used to weld hard thermoplastic plastics, but also to process fabrics and films. The main components of an ultrasonic welding system include an ultrasonic generator, a transducer/horn/weld head triple, a mold and a rack. Linear vibration friction welding melts plastics by using the friction heat generated at the interface of two workpieces to be welded. Thermal energy comes from a certain pressure, a workpiece in another surface with a certain displacement or amplitude of reciprocating movement. Once the desired welding degree is reached, the vibration will stop, and there will still be a certain amount of pressure applied to the two workpieces, so that just welded part of the cooling, solidification, thus forming a close bonding. Track type vibration friction welding is a method of welding by friction heat energy. In rail vibration friction welding, the upper part of the workpiece moves at a fixed speed on the track - circular motion in all directions. The movement can generate heat, so that the welding parts of the two plastic parts reach the melting point. Once the plastic begins to melt, the movement stops, and the welded parts of the two workpieces solidify and bond firmly together. A small clamping force causes the workpiece to undergo minimal deformation, and a workpiece less than 10 inches in diameter can be welded using track vibration friction.

TAG ultrasonic: ultrasonic transducer manufacture krautkramer ultrasonic transducers ultrasonic transducer buy