Home > NEWS > Industry Information > Rubber cutting ultrasonic generator 20khz/40khz/2000W

Rubber cutting ultrasonic generator 20khz/40khz/2000W

2018-09-26 14:38 admin

Ultrasound rubber cutting machine is a kind of equipment which uses ultrasonic energy to cut and process. Its biggest characteristic is that it does not need cutting edge. Or, not in the traditional sense. The traditional cutting is to use the cutting tool with sharp edges to press the cutting material. This pressure is concentrated at the edge, the pressure is very large, exceeding the shear strength of the material to be cut, the material molecule bond is pulled apart, is cut. Because the material is pulled apart by strong pressure, the cutting tool edge should be very sharp, and the material itself has to withstand relatively large pressure. For soft, elastic materials, cutting efficiency is not high.

The principle of ultrasonic rubber cutting machine is totally different, it is through the ultrasonic energy, will be cut material local heating melting, so as to achieve the purpose of cutting materials. Therefore, ultrasonic cutting does not require sharp edges, nor does it require a lot of pressure, will not cause material to be cut edge collapse, damage. At the same time, due to the ultrasonic vibration of the cutting tool, the friction resistance is very small, the cutting material is not easy to adhere to the blade. This is especially effective for viscous and elastic materials, frozen materials, such as food, rubber materials, objects that are inconvenient to pressurize, etc.

Ultrasound rubber cutting machine also has a great advantage, it is cutting at the same time in the cutting part of the fusion, cutting part is perfectly sealed, will not cause textile materials flying edge.

Ultrasound rubber cutting machine directly loads the ultrasonic energy onto the cutter, and the cutter becomes a cutter with ultrasonic wave. In cutting materials, the material is mainly softened and melted by ultrasonic energy. The cutting edge of the cutter only plays the role of slot location, ultrasonic energy output, separating materials. This cutting method is suitable for cutting materials that are inconvenient to set up chopping boards, such as thick, thick and long. For example, raw glue cutting, pipe cutting, frozen meat, candy, chocolate cutting, cake cutting, printed circuit boards, etc.

The basic structure of ultrasonic cutting machine is similar to ultrasonic cutting machine, but the ultrasonic output part is not a cutting tool, but a traditional ultrasonic plane die. Here, the mold is equivalent to a piece of chopping board. But this is a chopping board for ultrasonic vibration. The cutting knife is still traditional, but the sharpness of the edge requirements have decreased, the life of the knife has greatly extended. This cutting method is suitable for cutting sheet materials, such as various trademarks, garment lace, fabric cutting, decorative bead cutting, natural fiber, synthetic fiber, non-woven fabric, artificial resin, paper, film and so on.

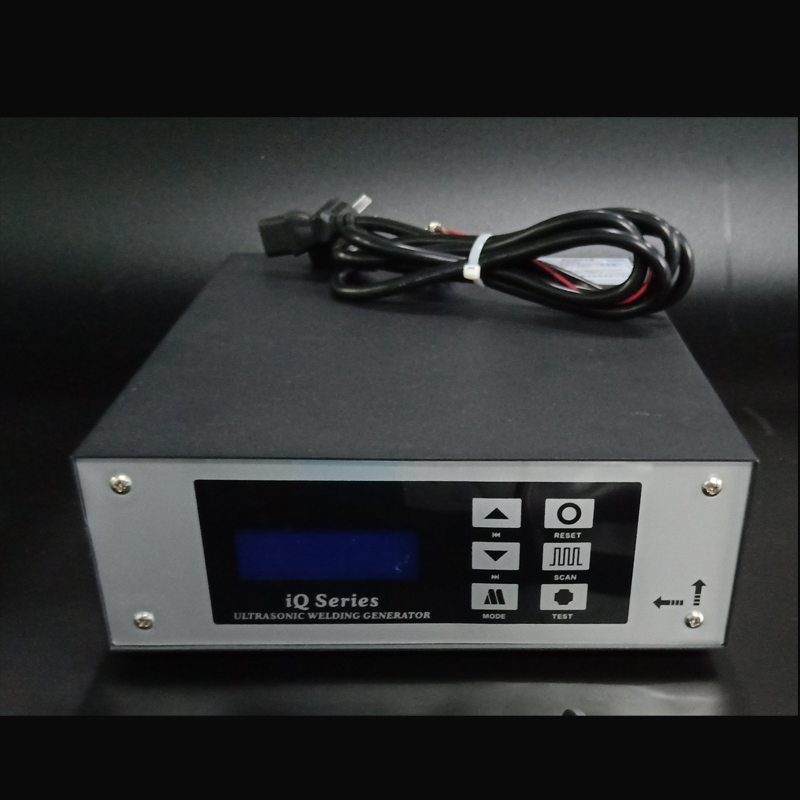

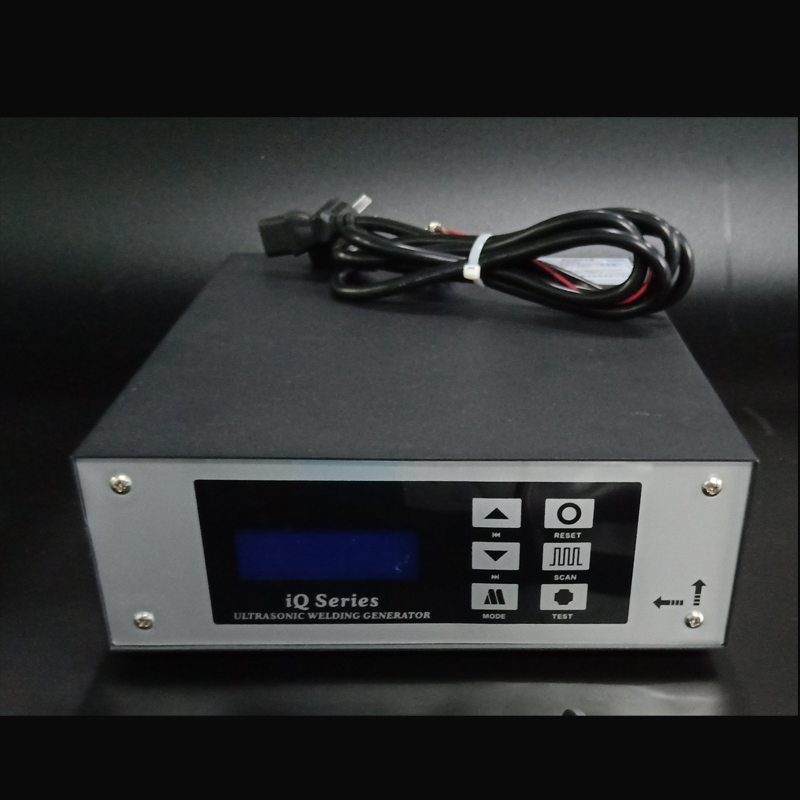

Rubber cutting ultrasonic generator 20khz/40khz/2000W

Original address:https://www.ultra-piezo.com/news/piezoceramic-ultrasonic/rubber-cutting-ultrasonic-generator-20khz-40khz-2000W.html

author:UCESONIC

TAG ultrasonic: 40khz ultrasonic generator 20khz ultrasonic generator