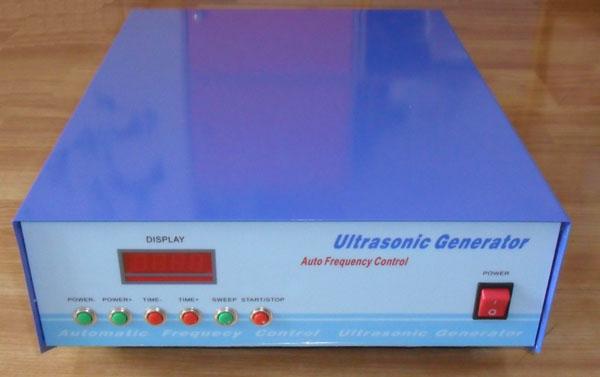

High power ultrasonic power supply

High power ultrasonic power supply combines ultrasonic cleaning in Japan and Europe advanced technology, the use of the latest circuit design, it is under the control of the use of microcomputer-excited lines, with a stable and reliable, ultrasonic power adjustable, and high conversion efficiency, as the industry technology leading ultrasonic generator, ultrasonic cleaning is widely used in industry. Its characteristics are as follows:

1 frequency automatic tracking: automatic head tracking output inductor and resonant vibration frequency of the cleaning effect will not change with temperature, humidity, water depth, oscillator aging and the use of time and other conditions change, so that the cleaning effect has been maintained at the highest level, the frequency deviation only 0.1 ‰ conversion efficiency ≥ 92%.

(2) a pure sine wave output current can be extended oscillator and signal generator's own life.

3 automatic sweep function: frequency sweep from 10Hz - 2KHz adjustable power sweep from 10% - 100%, so that a better cleaning effect.

4 ≤ 1% output current ripple effect to make cleaning more stable oscillator can be well protected from damage.

5 closed-loop control, the output current is more stable, so that current will not change with input voltage, oscillator aging conditions change, sustainable power to keep strong.

6 adjustable output power.

7 shows the output current, frequency tracking direction, over-temperature indication, output short circuit indication, vibration head failure indication. Can be more intuitive understanding of their work status.

8 Protection: power protection, overcurrent protection, overvoltage protection, undervoltage protection, frequency tracking failure and over temperature protection, output short circuit protection, under all of the different states and the oscillator signal generator to protect and prolong whole working life.

9 Power shock circuit, soft start to prevent excessive vibration instantaneous power head damage.

|

Type |

Power(W) |

Frequency (KHz) |

|

UCE—UG300W |

300 |

20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

|

UCE—UG500W |

500 |

20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

|

UCE—UG600W |

600 |

20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

|

UCE—UG900W |

900 |

20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

|

UCE—UG1000W |

1000 |

20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

|

UCE—UG1200W |

1200 |

20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

|

UCE—UG1500W |

1500 |

20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

|

UCE—UG1800W |

1800 |

20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

|

UCE—UG2000W |

2000 |

20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

|

UCE—UG2400W |

2400 |

20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

|

High Frequency |

500W-1200W |

65-80 |

|

High Frequency |

500W-1200W |

120-135 |

more:

piezo Transducer ultrasonic welding transducer

Ultrasonic Cleaner ultrasonic generator

ultrasonic cleaning machine ultrasonic single tank cleaner

US equipment for biodiesel Ultrasonic reactor for biodiesel

ultrasonic transducer circuit ultrasonic welding generator

Piezo ceramic(PZT) ring chip for industrial ultrasonic cleaner Piezo Ceramic(PZT) chip for Ultrasonic Welding Machine