Piezoelectric ceramics:

When the voltage applied to the piezoelectric ceramics, it will vary with voltage and frequency of changes in the mechanical deformation. On the other hand, when the vibration of piezoelectric ceramics, it will generate a charge. Using this principle, when given by the two piezoelectric ceramic or a piezoelectric ceramic and a metal film consisting of vibrator, the so-called called bimorphs, apply an electrical signal, it will emit ultrasonic vibration due to bending. Conversely, when applied to bimorphs ultrasonic vibration, it will generate an electrical signal. Based on the above role, it can be used as a piezoelectric ceramic ultrasonic transducer.

Piezoelectric ceramics is an electronic component sounds, two brass circular electrodes in the middle into the piezoelectric ceramic dielectric material, when the two electrodes connected to the exchange above the audio signal, the piezoelectric film based on the size of the signal frequency to vibrate and produce sound to. Piezoelectric ceramics as simple low cost, widely used in electrical and electronic aspects such as: toys, pronunciation electronic watches, electronic equipment, electronic watches and clocks, timers and so on.

Ultrasonic transducer:

(1) ultrasonic cleaning transducer

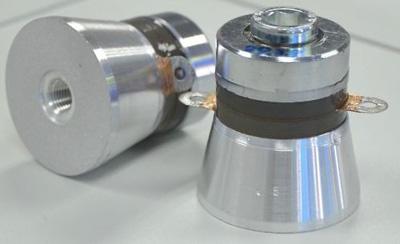

Ultrasonic transducer is to convert electrical energy into mechanical energy (ultrasonic) devices, one of the most mature and reliable energy is the piezoelectric effect with the acoustic energy conversion device, known as the piezoelectric transducer. It consists of the central piezoelectric ceramic components, before and after the metal cover, pre-stressed screw electrodes and insulating tubes. This sandwich transducer (bolt-type transducer) changes in load produce stable ultrasound, ultrasound-driven power source is to obtain the most basic method. Depending on the design, they are columnar form (front metal cover the same diameter), inverted horn (front cover too narrow in diameter by arc), column steel back cover, cylindrical middle section and so on.

Central ultrasonic transducer piezoelectric ceramic components, before and after the metal cover, pre-stressed screw electrodes and insulating tubes. This sandwich transducer (also known as: bolt-type transducer) changes in load produce stable ultrasound, ultrasound-driven power source is to obtain the most basic method. Depending on the design of ultrasonic transducers are cylindrical shape (diameter of the same before and after the metal cover), speaker type (front cover too narrow in diameter by arc), the middle section structure of cylindrical shape.

Main features:

High efficiency: high mechanical quality factor, the resonant frequency of the electro-acoustic work available to a very high conversion efficiency.

Large amplitude: The computer optimized structure, the vibration ratio is high, large amplitude of the front cover.

Big power: the role of the screw in the pre-stressed, the piezoelectric ceramic energy to be the greatest play.

(2) ultrasonic welding transducer

Ultrasonic plastic welding transducer is the first vibration transducer generates tens of thousands of times per second high-frequency vibration, resulting in local heat, melt the welding zone of plastic end up welding purposes. Ultrasonic plastic welding transducer commonly used bolt clamping structure of the longitudinal time around, and together with the fixture is connected to the first, composed of plastic vibration welding system.

Ultrasonic welding transducer, start-up cleaning transducer principles with the same, but it's more powerful to withstand. An ultra-high-power acoustic transducer. Often with shaped head style and working horn is composed of plastic vibration welding system. To complete the plastic, metal and other materials, ultrasonic welding.

Ultrasonic welding is generated by the ultrasonic transducer vibration, pressure on the state of the material being welded high friction contact with the surface of the gap junction hot cozy effect, so as to achieve soldering purposes.

Ultrasonic welding transducer is a work of high-power gap transducer, generally transient and constant peak power to calculate the size of its power.

Overpressure produced by high-power, high-sensitivity piezoelectric ceramic element, and a variety of ultrasonic industrial, medical transducer, used: washing machine, welding machine, polishing machine, drilling machines, metal welding machines, detector, B- type of diagnostic, Doppler, scaler, focused ultrasound, ultrasound beauty machine.

Ultrasonic generator

Issued by the ultrasonic generator frequency oscillation signal by the transducer and converted into high frequency mechanical vibration transmitted to the media - cleaning solvents, ultrasonic cleaning fluid density and white in the forward radiation, the number of the liquid flow generated of thousands of tiny bubbles. The vertical transmission of ultrasound bubbles in the negative pressure zone formation, growth, and rapidly closed in positive zone. In this is called "cavitation" effect of the process, the bubbles can form more than 1000 closed pressure transients, momentary high pressure continuously as a series of small "explosion" continue to impact the surface of the object, so objects cracks in the dirt surface and rapidly falling off, so as to achieve the purpose of cleaning the surface of the object.

Ultrasonic generator advantages, features the use of:

1, the NC was washed several times.

2, CNC digital ultrasonic power.

3 digital soft start, digital soft-off. Effective protection of the IGBT. And reduce the impact of the grid.

4. Output current ripple ≤ 2%, the cleaning effect is more stable oscillator can be well protected from damage.

5. Pure sine wave AC current.

6. Protection: power protection, overcurrent protection, overvoltage protection, undervoltage protection, the oscillator signal generator to protect and prolong the working life of the machine (you can play the role of isolation, when the oscillator is damaged, will not cause the same time generator of the damage, which in turn is the same reason, the occurrence of short circuit can automatically adapt to, and will not damage the machine).

more:

piezo Transducer ultrasonic welding transducer

Ultrasonic Cleaner ultrasonic generator

ultrasonic cleaning machine ultrasonic single tank cleaner

US equipment for biodiesel Ultrasonic reactor for biodiesel

ultrasonic transducer circuit ultrasonic welding generator

Piezo ceramic(PZT) ring chip for industrial ultrasonic cleaner Piezo Ceramic(PZT) chip for Ultrasonic Welding Machine