Home > NEWS > Industry Information > ultrasonic cleaning machines suppliers/manufacturers

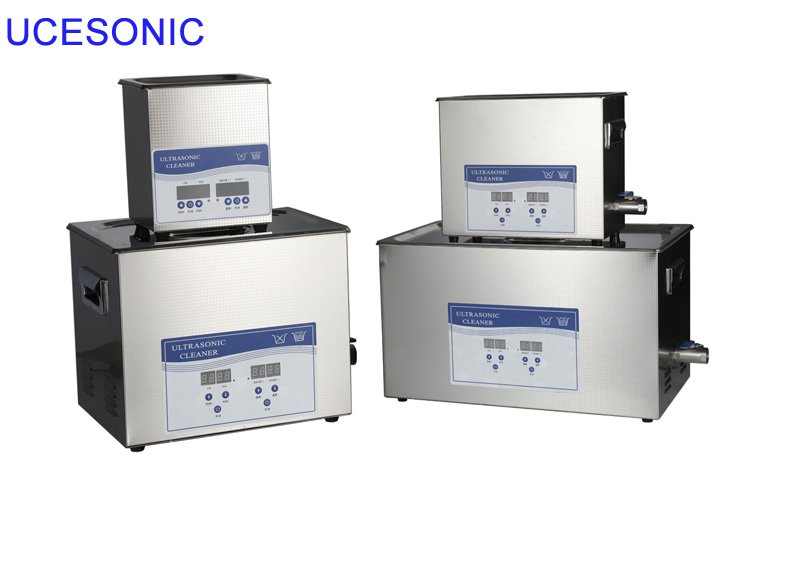

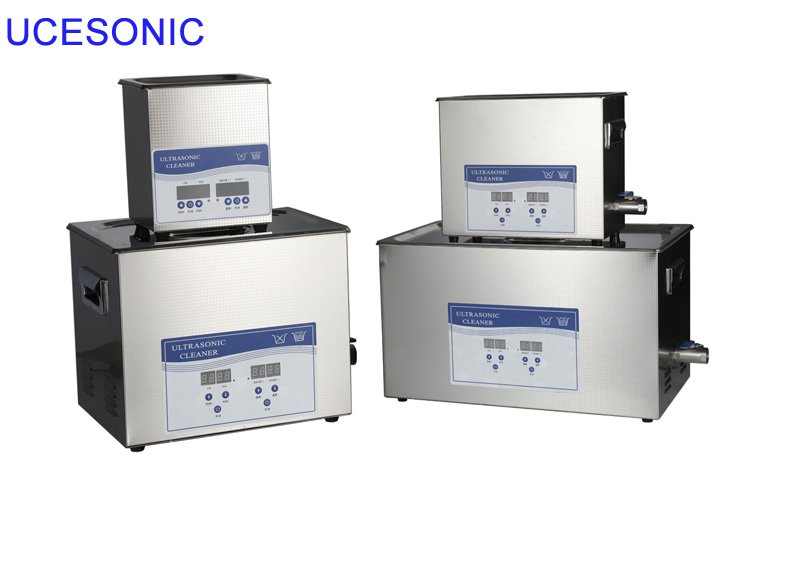

ultrasonic cleaning machines suppliers/manufacturers

2018-10-06 23:52 admin

Ultrasound cleaning first appeared in the early 1930s, when technicians at a laboratory of the American Radio Company in New Jersey tried to clean certain objects with a homemade, simple ultrasonic cleaning system, but the experiment was unsuccessful. On this basis, ultrasonic cleaning technology in the 1950s has been greatly developed, the ultrasonic frequency used at that time was between 20 kHz and 40 kHz. This range of ultrasound is used in thousands of different workplaces, many of which are not very effective by other cleaning methods. Ultrasound can exert tremendous energy on the workpiece, especially for removing dirt firmly attached to the substrate. However, in some cases, the strong energy of ultrasound can also damage the dirty and fragile substrate materials. Over the past decade, there have been some technological innovations in the field of ultrasound, which have improved the safety factor of removing dirt from sensitive substrates. During this period, the ultrasonic technology, especially the medium and high frequency ultrasonic cleaning technology has a new development, and become the highlight of the industry.

In recent years, it has been found that cleaning with Mega-Sonic waves (called conventional or low-frequency ultrasonic waves at or below 40 kHz depending on the frequency of ultrasonic waves, or high-frequency ultrasonic waves above 1 000 kHz, or Mega-Sonic waves for short) can remove ultrafine dirt particles on the surface of semiconductor materials without damaging the substrate materials. The surface of the surface. At present, this technology has been popularized very quickly.

Factors affecting cleaning

Cleaning medium: ultrasonic cleaning, generally there are two kinds of cleaning agents, that is, chemical solvents and water based cleaning agents. The chemical action of cleaning medium can accelerate the effect of ultrasonic cleaning. Ultrasonic cleaning is a physical action. Combining the two functions, the object can be cleaned thoroughly and thoroughly.

Power density: the higher the power density of ultrasonic, the stronger the cavitation effect, the faster the speed, the better the cleaning effect. But for the precision surface finish of very high objects, using long time high power density cleaning will cause cavitation and corrosion on the surface of the objects.

Ultrasound frequency: Suitable for coarse, dirty, initial cleaning of workpiece, high frequency, strong directivity of ultrasonic, suitable for fine cleaning of objects.

Cleaning High Temperature: Generally speaking, the ultrasonic cavitation effect is the best when the temperature is between 50 degrees C and 60 degrees C, and the cleaning agent is not the higher the temperature, the more significant the effect, it may be high temperature failure. Usually the ultrasonic cleaning effect has become worse when the ultrasonic exceeds 85 degrees C. Therefore, the actual application of ultrasonic cleaning, the use of 50 degrees C~70 degrees C working temperature.

ultrasonic cleaning machines suppliers/manufacturers

Original address:https://www.ultra-piezo.com/news/piezoceramic-ultrasonic/ultrasonic-cleaning-machines-suppliers-manufacturers.html

author:UCESONIC

TAG ultrasonic: ultrasonic jewelry cleaning machine reviews industrial ultrasonic cleaning machines Ultrasonic Machines and Cleaning Equipments Manufacturers